Stahlwassertank für Flaschenwasserherstellung

$109999-119999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Land,Ocean |

| Hafen: | ALASHANKOU,SHANGHAI,TIANJIN |

$109999-119999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Land,Ocean |

| Hafen: | ALASHANKOU,SHANGHAI,TIANJIN |

Modell: LPT3000

Marke: Lipp

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

|

- Waste water tank

- Sewage sludge tank

- Process water tank

- Storage tank

- Firefighting water tank

|

- Mixing and compensation tank

- Buffer tank

- Stackable sludge tank

- Filtrate water tank

- Final sedimentation tank

Other special tanks on request

|

|

Technical Data

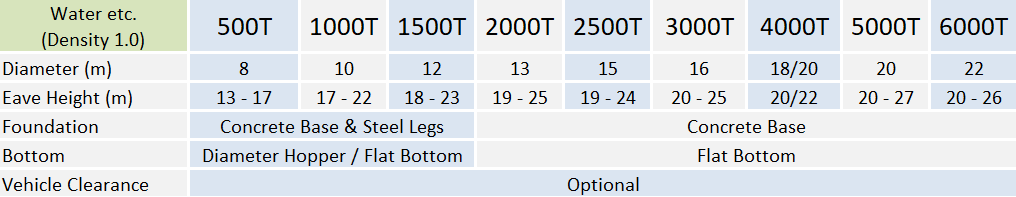

Diameter: 3.5 - 38 m

Height: 5 - 23 m

Volume: 100m3 - 10,000m3

pH level: 3 - 13

|

Material

Galvanized steel / black steel

Stainless steel (SUS304, SUS316...)

Verinox (stainless steel + galvanized steel)

|

Accessories

Roofs and covers

Tank bottom

Pumping and mixing technology

Tank insulation

Stairways, ladders, platforms, connection pieces, manholes, etc.

|

|

|

Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety. Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions.

|

|

- Edgeless, smooth finish

- Maximum leak tightness

- Automated, efficient production on site

- Low installation and investment

- Minimal installation space required

|

- High static and dynamic stability

- Available in stainless steel, VERINOX® stainless steel or galvanized steel/black steel

- Substrate-flexible due to specific material selection

- Low maintenance costs

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture with its German partner, Lipp GmbH, the founder of Lipp® silo.Over the years, the company has participated in the construction of multiple international projects such as the Ulan Cement Plant in Mongolia, Pyongyang in North Korea, and the Rason Cement Plant. With rich construction experience, tenacious work style, and excellent engineering quality, the company has won the favor of foreign customers.

|

|

|

Advantages of Lipu Steel Plate Warehouse

|

|

|

1.Durability and Structural Integrity

Steel silos are built to withstand harsh environmental conditions and heavy loads, ensuring long-term reliability. The use of Galvanized steel coil (2-4mm) and advanced roll-forming techniques enhances their resistance to wear and deformation. 2.Moisture and Contamination Protection Their airtight design prevents moisture ingress, which is critical for maintaining cement quality. Steel construction also minimizes risks of pest infiltration or chemical reactions that could degrade stored materials. 3.Efficient Material Handling Integrated systems like screw conveyors (commonly used in cement silos) enable automated and precise material transfer, reducing manual labor and improving operational efficiency in batching plants. |

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|