2500t Raps -Lagerung Siloöl -Herstellung Material Silo

$78888-98888 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Land,Ocean |

| Hafen: | SHANGHAI,QINGDAO,ALASHANKOU |

$78888-98888 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Land,Ocean |

| Hafen: | SHANGHAI,QINGDAO,ALASHANKOU |

Modell: LPG2500

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

| Wheat, corn, rice, paddy grain, barley, soy bean, soy bean meal, etc. | |

|

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

Dimension Sheet:

|

|

|

|

|

Advantages of Lipu Steel Plate Warehouse

1.Durability and Structural Integrity

Steel silos are built to withstand harsh environmental conditions and heavy loads, ensuring long-term reliability. The use of Galvanized steel coil (2-4mm) and advanced roll-forming techniques enhances their resistance to wear and deformation.

2.Moisture and Contamination Protection

Their airtight design prevents moisture ingress, which is critical for maintaining cement quality. Steel construction also minimizes risks of pest infiltration or chemical reactions that could degrade stored materials.

3.Efficient Material Handling

Integrated systems like screw conveyors (commonly used in cement silos) enable automated and precise material transfer, reducing manual labor and improving operational efficiency in batching plants.

|

|

|

|

|

|

Application scenarios

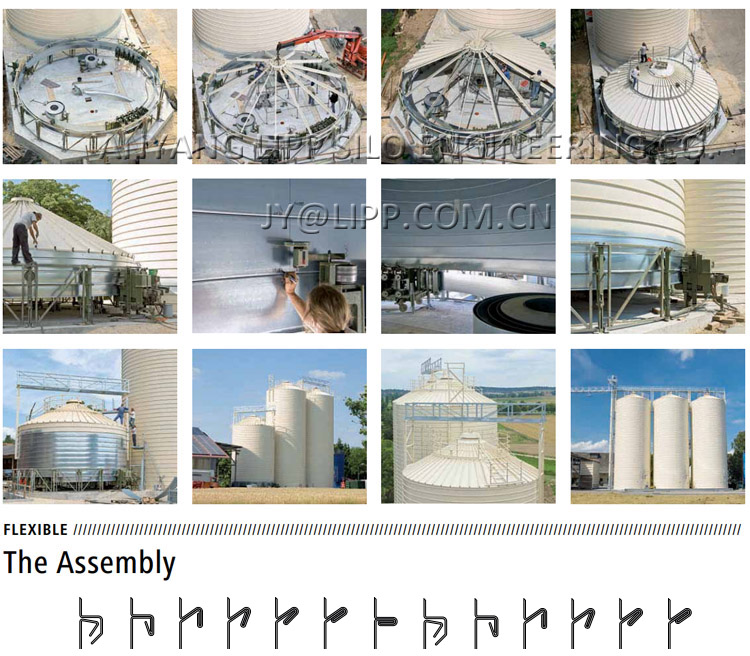

Cylindrical silos for bulk material storage Lipp's innovative mobile manufacturing system enables cost-effective installation of large-capacity steel silos (up to 10,000 m³) at any project location. The engineered roof configuration provides ATEX-compliant explosion protection for enhanced operational safety.

Containers for water, waste water, sewage sludge In liquid container construction, the selection of a suitable material is decisive for preventing corrosion and ensuring the greatest possible impermeability and safety. Possible materials include aluminum, galvanized steel or high-alloy stainless steels. The cost-benefit ratio is especially favorable with the material combination “Verinox” developed by Lipp. |

|

Containers for bio, sewage and landfill gas

Lip's innovative atmospheric dry gas storage technology has achieved excellent operational performance with functional safety level certification, extremely low annual failure rate, and significantly reduced energy consumption through its unique patented design. This technology has been successfully applied in over 30 countries worldwide for more than 20 years, with a total of 200+gas storage facilities built.

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|