Edelstahl -Wassertank zur Trinkwasserlagerung

$109999-112999 /Set/Sets

| Zahlungsart: | T/T,L/C,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | S |

$109999-112999 /Set/Sets

| Zahlungsart: | T/T,L/C,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | S |

Modell: LPT3000

Marke: Lipp

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

|

Technical Data

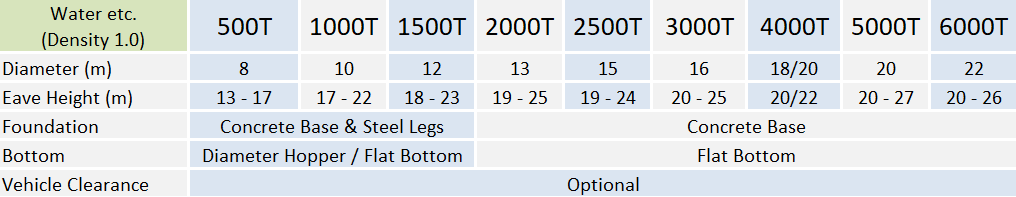

Diameter: 3.5 - 38 m

Height: 5 - 23 m

Volume: 100m3 - 10,000m3

pH level: 3 - 13

|

Material

Galvanized steel / black steel

Stainless steel (SUS304, SUS316...)

Verinox (stainless steel + galvanized steel)

|

Accessories

Roofs and covers

Tank bottom

Pumping and mixing technology

Tank insulation

Stairways, ladders, platforms, connection pieces, manholes, etc.

|

|

|

Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety.

Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions.

|

|

- Edgeless, smooth finish

- Maximum leak tightness

- Automated, efficient production on site

- Low installation and investment

|

- High static and dynamic stability

- Available in stainless steel, VERINOX® stainless steel or galvanized steel/black steel

- Substrate-flexible due to specific material selection

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture with its German partner, Lipp GmbH, the founder of Lipp® silo. Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc.

In 1994, it undertook the PT. indro project in Indonesia, becoming a domestic steel silo industry enterprise capable of undertaking foreign projects, marking Anyang Lipu's entry into the world.

As one of the pioneers in the steel plate warehouse industry, Anyang Lipu adheres to the concept of "people-oriented, pragmatic and enterprising", continues to carry forward the spirit of "innovative operation, scientific management, standardized operation, honest service, and creating first-class", and adheres to the principle of "mutual benefit and common development".

Over the years, the company has participated in the construction of multiple international projects, including PT. indro in Indonesia, Almaty Cement Plant in Kazakhstan, Gansai Hydropower Station in Cambodia, Zambia National Grain Reserve, Fuqiang Burk Cement Plant in Indonesia, Emperor Cement Plant in Egypt, RAI Cement in Kenya, China National Materials Overseas Oman Cement Grinding Plant Project, YOJIN Myanmar Cement Project in South Korea, Gezhouba Laos Hydropower Station, Hydropower Group Maitrong Hydropower Station, Ulan Cement Plant in Mongolia, Pyongyang in North Korea, and Rason Cement Plant. With rich construction experience, tenacious work style, and excellent engineering quality, the company has won the favor of foreign customers.

|

|

|

Milestones

|

|

|

1985

|

We built the first Lipp silo for Xixia Distillery in Shandong Province, China, filled the gap of Chinese steel silo construction. |

| 1991 | We built the highest steel silo with the height 33m in Lianyungang, it became a milestone in Chinese storage field. |

| 1993 | we built the first silo design institute of China; |

| 1996 | We became the first Chinese company won the international invitation of tender in steel silo field (German Steinecker GMBH, New Zealand Lionna Than Company ) |

| 1998 | We built the biggest steel silo for Uni-President group of Taiwan. |

| 2001 | We built the biggest steel tank (dia. 38m) for Chengyang waste water treatment factory, Tsingdao. |

| 2006 | Annual turnover exceeded RMB120 million; turnover exceeds 100 million for 3 consecutive years. |

| 2011 | Given the title “National High & New Technology Enterprise” Annual turnover exceeded RMB250 million |

| 2013 | Anyang Lipp built the 10000th steel silo, erected silos over 14 countries; |

| 2014 |

Became the first to get ISO9000, ISO14001 and ISO45001 certificates among the peers |

| 2018 |

Introduce SM80 equipment from Germany, starting making spiral welding silo |

| 2019 |

Company move to the modernized brand-new facility |

| 2021 | Secured Anyang Eco-Industrial Park EPC+O project with contract price CNY470 million |

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|

|

Potable water storage tanks are specialized containers designed to safely store drinking water while maintaining its quality and compliance with health standards. Key features include: Construction & Materials These tanks are typically made from durable, corrosion-resistant materials such as polyethylene or steel with protective coatings (e.g., double-layer 0.40mm thickness coatings) to prevent contamination or stainless steel. They are engineered to withstand environmental stressors, ensuring long-term structural integrity. Compliance & Safety Manufactured to meet strict regulatory standards, they ensure safe storage by preventing bacterial growth and chemical leaching. Some designs incorporate stratification management, such as floating pump intakes, to avoid drawing water from surface layers prone to particulate accumulation. Applications Used for rainwater harvesting, municipal water supply, and emergency water reserves. Suitable for both residential and industrial settings due to their scalable designs. Maintenance Regular inspections and adherence to environmental compliance protocols are critical to preserving water quality and tank durability. These tanks prioritize hygiene, durability, and regulatory adherence, making them essential for reliable potable water management systems. |

|