Gips -Pulver -Silo -Rohstofflager Silo

$62999-64999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,SHANGHAI,TIANJIN |

$62999-64999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,SHANGHAI,TIANJIN |

Modell: LPC2000

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

|

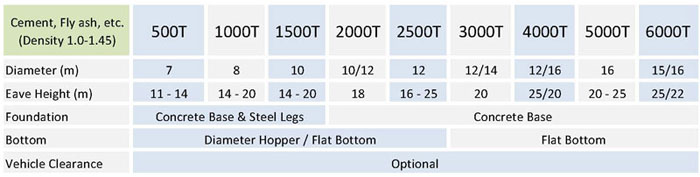

Dimension Sheet:

|

|

|

|

|

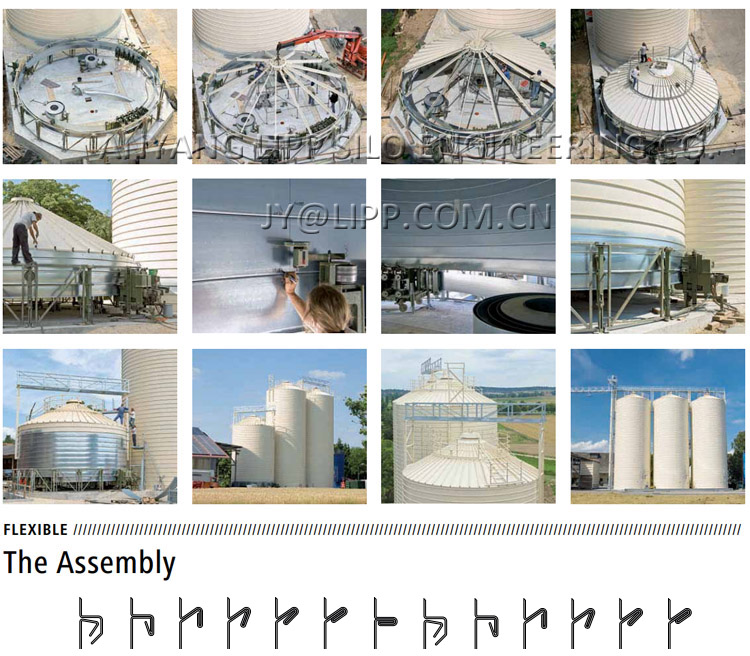

LIPP® DOUBLE-SEAM / SPIRAL RIB

|

|

|

Traditional storage solutions frequently fail to meet the requirements for secure and efficient containment of bulk materials, whether solid or liquid. These outdated designs commonly lead to:

1.Early-stage material degradation from corrosion 2.Containment failures resulting in leaks 3.Compromised safety standards Our response:

Develop highly adaptable storage tanks with infinitely expandable dimensions and customized substrates according to demand. Through topology optimization design, eliminate terrain constraints and enable infrastructure to actively adapt to your business scenario, rather than the opposite. |

|

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

1.Unrivaled Structural Performance

Our steel silos are designed to deliver outstanding structural integrity, capable of withstanding the most demanding operational environments. Utilizing high-grade galvanized steel and state-of-the-art forming techniques, these storage solutions offer industry-leading protection against corrosion and maintain dimensional stability throughout their extended service life. 2.Premium Storage Environment Protection The airtight engineering of our silo systems ensures complete moisture barrier protection, maintaining ideal storage conditions for cement and other sensitive materials. Beyond humidity control, the robust steel construction forms an impenetrable barrier against external contaminants, biological threats, and adverse chemical reactions that could affect stored product quality.

3. Intelligent Material Management Engineered for modern industrial operations, our silos feature fully integrated material handling technology with automated screw conveyor systems specifically optimized for cement applications. This advanced configuration enables precise material flow control, minimizes manual intervention, and maximizes throughput efficiency in production environments. |

|

|

|

|

About Us

Anyang Lipu Silo Engineering Co., Ltd. is affiliated with Sawa, the inventor of Lipu's patented technology Mr. Lipu's German Lipu company is a Sino German joint venture specializing in the production of Lipu style steel plate silos, with a second level qualification for steel structure engineering and environmental engineering contracting. With strong technical strength, talent advantages, and a good reputation accumulated over the years, the company has been actively expanding into international markets since the late 1990s, making significant breakthroughs in industries such as grain, cement, building materials, and environmental protection. |

|

|

Milestones

|

|

1985

|

We built the first Lipp silo for Xixia Distillery in Shandong Province, China, filled the gap of Chinese steel silo construction. |

| 1991 | We built the highest steel silo with the height 33m in Lianyungang, it became a milestone in Chinese storage field. |

| 1993 | we built the first silo design institute of China; |

| 1996 | We became the first Chinese company won the international invitation of tender in steel silo field (German Steinecker GMBH, New Zealand Lionna Than Company ) |

| 1998 | We built the biggest steel silo for Uni-President group of Taiwan. |

| 2001 | We built the biggest steel tank (dia. 38m) for Chengyang waste water treatment factory, Tsingdao. |

| 2006 | Annual turnover exceeded RMB120 million; turnover exceeds 100 million for 3 consecutive years. |

| 2011 | Given the title “National High & New Technology Enterprise” Annual turnover exceeded RMB250 million |

| 2012 | The chicken farm CSTR anaerobic reaction system (total capacity 7000m3) in Beijing was finished, marking a big step forward for China in the biogas exploitation field. |

| 2013 | Anyang Lipp built the 10000th steel silo, erected silos over 14 countries; |

| 2014 |

Became the first to get ISO9000, ISO14001 and ISO45001 certificates among the peers |

| 2018 |

Introduce SM80 equipment from Germany, starting making spiral welding silo |

| 2019 |

Company move to the modernized brand-new facility |

| 2021 | Secured Anyang Eco-Industrial Park EPC+O project with contract price CNY470 million |

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|