Hydro -Station Silo -Bindungsmaterial -Speicher Silo

$76999-79999 /Set/Sets

| Zahlungsart: | T/T,L/C,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,QINGDAO,SHANGHAI |

$76999-79999 /Set/Sets

| Zahlungsart: | T/T,L/C,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,QINGDAO,SHANGHAI |

Modell: LPC1000

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

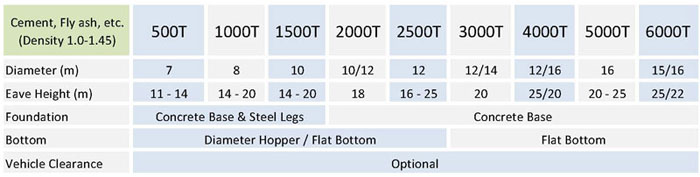

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

Dimension Sheet:

|

|

|

|

|

What's "Binding Material"? Definition A binding material refers to substances (e.g., cement, fly ash, or additives) that bind aggregates or particles together to form cohesive mixtures like concrete or mortar. These materials ensure structural integrity in construction applications. Key Types & Roles Cement: Primary binder in concrete, reacting with water to harden and bind aggregates14. Fly Ash/Silica Powder: Supplementary binders enhancing durability and reducing cement consumption in mixes. Chemical Additives: Adjust setting time, workability, or strength of the final product. Applications Concrete Production: Critical for forming concrete slabs, foundations, and prefabricated structures. Road Construction: Binds asphalt or cement with aggregates to create stable surfaces. Industrial Storage: Stored in specialized silos (e.g., 500T steel silos) to prevent contamination and ensure consistent quality. Storage Solutions 500T Steel Silos: Designed to store binding materials like cement or fly ash, featuring: Corrosion-resistant steel construction. Sealed structures to block moisture and contaminants. Modular bolted designs for easy assembly and scalability. This integration of binding materials with advanced storage systems ensures efficient, large-scale production in construction and industrial sectors. |

|

|

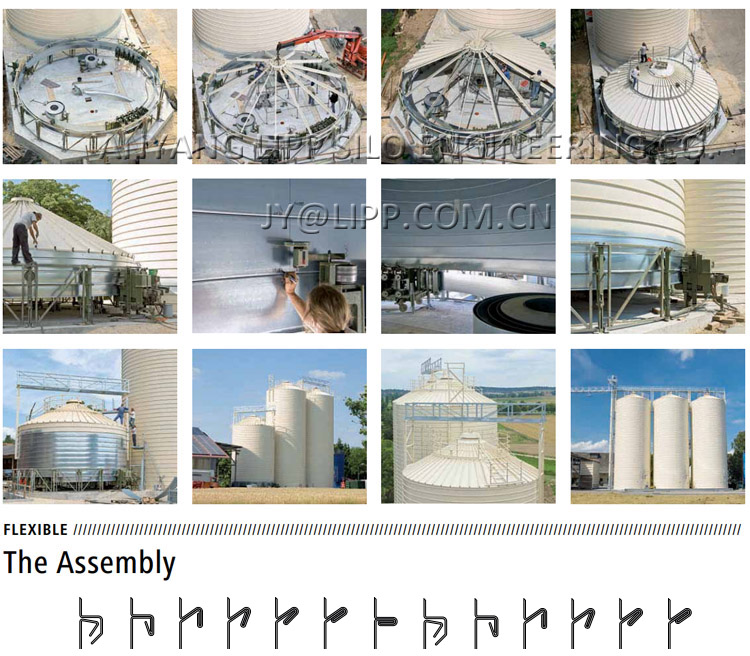

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs Ø Minimal installation space required |

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection Ø Low maintenance costs |

|

|

|

About Us

|

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture established between Anyang Lipp Silo Co.,Ltd and its German partner, Lipp GmbH, specializing in the production of Lipp silo, also known as spiral silo. With registered capital of RMB20 million, fixed assets over RMB150 million, Anyang Lipp is also a certified contractor of steel structure construction and environmental-friendly projects. Among all its competitors, the company is the first to get ISO9000 certificate, capable of doing research, design, fabrication and installation.

Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc. With superior product and service, Anyang Lipp has served many domestic and international enterprises including Carlsberg, Heineken, Wilmar, M+W Group, Netafim, Lafarge, Royal Cement, COFCO, etc.

With over 500 employees, Anyang Lipp can build steel silo with the total capacity of 5 million m3 per year. About 120 technical staffs and engineers strengthen the company’s competitive edge, making us the most productive and reputed steel silo manufacturer in China.

|

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|

|

Spiral silos (constructed using spiral-rolling technology) and bolted silos (assembled from bolted steel panels) differ significantly in design and performance. Here are the key advantages of spiral silos over bolted silos: 1. Seamless Construction & Superior Strength Spiral silos are formed by continuously coiling and welding steel strips into a helical shape, creating a seamless, monolithic structure. This eliminates weak points at joints, improving resistance to internal and external pressures (e.g., wind, seismic loads, or material expansion). Bolted silos rely on panel connections, which are prone to stress concentration, bolt loosening, or corrosion over time, compromising structural integrity. 2. Enhanced Airtightness The welded seams of spiral silos provide superior airtightness, minimizing moisture ingress and contamination risks—critical for moisture-sensitive materials like cement. Bolted silos often require sealants or gaskets at panel joints, which degrade over time, leading to leaks and potential material spoilage. 3. Faster On-Site Installation Spiral silos are built on-site using specialized spiral-rolling machines, reducing transportation costs for large structures and enabling faster construction (e.g., a 1,000-ton silo can be completed in 5–7 days). Bolted silos require transporting prefabricated panels and time-consuming assembly, increasing labor and logistical costs. 4. Lower Maintenance Costs Spiral silos have no bolts or joints to inspect or tighten, reducing long-term maintenance needs. Corrosion-resistant coatings (e.g., galvanizing) are applied uniformly during fabrication. Bolted silos need regular inspections for bolt integrity, sealant wear, and corrosion at joints, raising lifecycle costs. 5. Better Load Distribution The helical design of spiral silos distributes mechanical and thermal stresses evenly, enhancing stability and longevity, even under dynamic loads (e.g., filling/emptying cycles). Bolted silos experience uneven stress at panel connections, increasing wear and fatigue risks. 6. Larger Capacity Potential Spiral technology allows for taller and wider silos (up to 30m+ in diameter and 50m+ in height) without structural compromises. Bolted silos face limitations in panel size and joint strength, restricting scalability. 7. Durability in Harsh Environments Spiral silos perform better in extreme weather (high winds, temperature fluctuations) due to their seamless, rigid design. Bolted silos are more vulnerable to joint failures or deformation under similar conditions. 8. Smoother Material Flow The smooth, continuous interior surface of spiral silos prevents material buildup and ensures consistent discharge—ideal for cohesive materials like cement. Bolted silos have ridges at panel joints, increasing the risk of material clogging or bridging. Applications Where Spiral Silos Excel: Large-scale cement storage, fly ash, grains, or powdered chemicals. Environments requiring airtightness, seismic resistance, or minimal maintenance. When Bolted Silos Might Be Preferable: Small-scale or temporary storage. Projects requiring disassembly and relocation.

In summary, spiral silos outperform bolted silos in durability, airtightness, maintenance efficiency, and scalability, making them the preferred choice for industrial bulk storage where reliability and longevity are paramount. |

|