Harbor Zementübertragungsstation Entladung Siloschiffbeladung

$128999-129999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Land,Ocean |

| Hafen: | SHANGHAI,TIANJIN,ALASHANKOU |

$128999-129999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Land,Ocean |

| Hafen: | SHANGHAI,TIANJIN,ALASHANKOU |

Modell: LPC8000

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

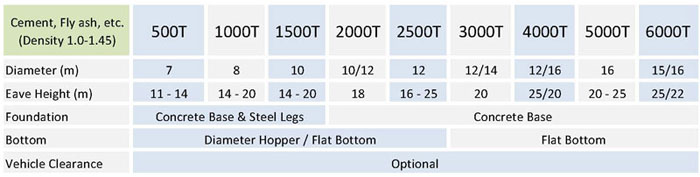

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

Specification:

|

|

| Customizable diameter of 3.5-38 meters Height 5-23 meters free configuration Using high-quality galvanized steel sheet with a thickness of 2.0-4.0mm Single warehouse capacity covers 100-7000 tons High standard rust prevention treatment |

|

|

Dimension Sheet:

|

|

|

|

|

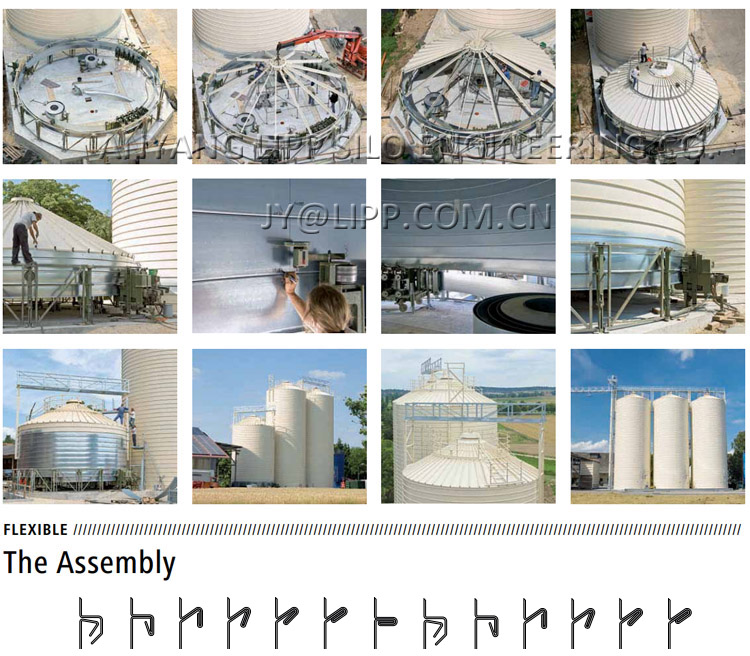

LIPP® DOUBLE-SEAM / SPIRAL RIB

|

|

|

Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety. Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions. |

|

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs Ø Minimal installation space required |

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection Ø Low maintenance costs |

|

|

|

About Us

|

|

|

|

|

Over the years, with rich project experience, rigorous construction style, and excellent engineering quality, we have successfully participated in multiple international key projects and won the trust and cooperation of global customers.

Representative projects include: Asia: Cambodia Gansai Hydropower Station, Gezhouba Laos Hydropower Station, Hydroelectric Group Maitrong Hydropower Station Africa: Zambia National Grain Reserve, Egypt Emperor Cement Plant, Kenya RAI Cement Project Middle East and Central Asia: Almaty Cement Plant in Kazakhstan, China National Materials Overseas Oman Cement Grinding Station, Ulan Cement Plant in Mongolia Southeast Asia: PT. Indro project in Indonesia, Fuqiang Bulk cement plant in Indonesia, YOJIN cement project in Myanmar, South Korea Other regions: Construction projects of cement plants in Pyongyang and Rason, North Korea |

|

|

Milestones

|

|

|

1985 Icebreaking Work (Establishment of Lipu Silo)

1993 Intelligent Manufacturing Engine (Design Institute Established) 1996 Sail to the Sea (German New Project) 2001 Engineering Miracle (Φ 38m Giant Tank) 2011 Technology Certification (National High tech) 2013 Global Footprint (14 countries) 2021 Model Innovation (EPC+O) |

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|