Schlackenpulverlager -Silo mit Betonbasis

$64999-69999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,TIANJIN,SHANGHAI |

$64999-69999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,TIANJIN,SHANGHAI |

Modell: LPC4000

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

| Herunterladen | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

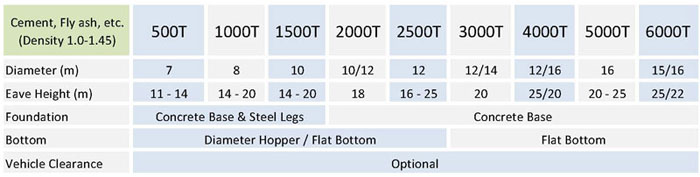

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

Dimension Sheet:

|

|

|

|

|

Advantages of Lipu Steel Plate Warehouse

|

|

|

Total Environmental Sealing

The hermetic silo design creates an impenetrable barrier against humidity, safeguarding cement from clumping and strength loss. Steel walls additionally block rodents, insects, and corrosive chemical interactions. Industrial-Grade Resilience Built to last with thick-gauge galvanized steel and advanced manufacturing processes, our silos maintain structural integrity under the toughest conditions, from hurricane-force winds to seismic activity. Efficient transportation and reduced reliance on manual labor By using automated tools such as built-in screw conveyors, fast and accurate material transfer can be achieved, improving production efficiency and reducing the need for manual operations. |

|

|

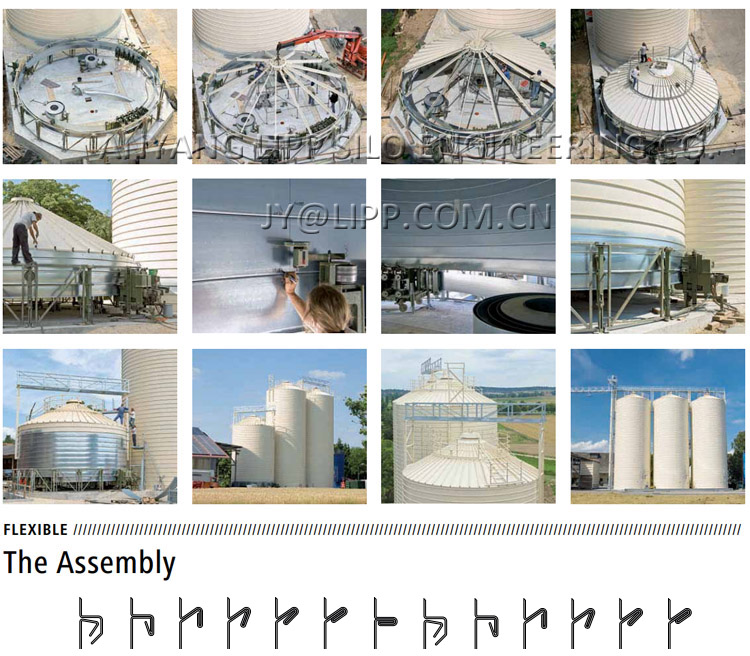

Onsite installation

With the transportable assembly devices also conceived by Lipp, steel bands can be assembled into containers - on site - in the desired size and with a variable diameter, in any location. A tested and largely automated manufacturing process permits fast, flexible, efficient assembly with a minimal installation space requirement. A Lipp Dual-Seam System is believed to be the fastest, simplest way to flexibly build reliable containers and tanks.

|

|

|

|

|

Milestones

|

|

1985

|

We built the first Lipp silo for Xixia Distillery in Shandong Province, China, filled the gap of Chinese steel silo construction. |

| 1991 | We built the highest steel silo with the height 33m in Lianyungang, it became a milestone in Chinese storage field. |

| 1993 | we built the first silo design institute of China; |

| 1996 | We became the first Chinese company won the international invitation of tender in steel silo field (German Steinecker GMBH, New Zealand Lionna Than Company ) |

| 1998 | We built the biggest steel silo for Uni-President group of Taiwan. |

| 2001 | We built the biggest steel tank (dia. 38m) for Chengyang waste water treatment factory, Tsingdao. |

| 2006 | Annual turnover exceeded RMB120 million; turnover exceeds 100 million for 3 consecutive years. |

| 2011 | Given the title “National High & New Technology Enterprise” Annual turnover exceeded RMB250 million |

| 2012 | The chicken farm CSTR anaerobic reaction system (total capacity 7000m3) in Beijing was finished, marking a big step forward for China in the biogas exploitation field. |

| 2013 | Anyang Lipp built the 10000th steel silo, erected silos over 14 countries; |

| 2014 |

Became the first to get ISO9000, ISO14001 and ISO45001 certificates among the peers |

| 2018 |

Introduce SM80 equipment from Germany, starting making spiral welding silo |

| 2019 |

Company move to the modernized brand-new facility |

| 2021 | Secured Anyang Eco-Industrial Park EPC+O project with contract price CNY470 million |

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|