Chargen -Pflanze Silo 500T Stahl Silo

$37999-40999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,QINGDAO,SHANGHAI |

$37999-40999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,QINGDAO,SHANGHAI |

Modell: LPC500

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

| Herunterladen | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

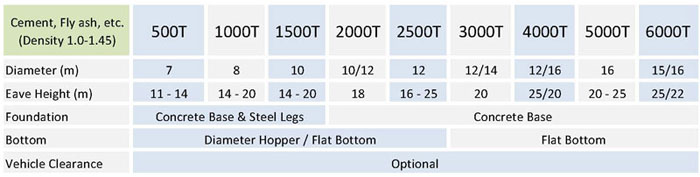

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

A 500T Steel Silo for Batching Plants is a industrial storage solution designed for concrete production facilities, primarily used to store bulk materials like cement, fly ash, silica powder, or other aggregates. Key features include: (fly ash silo, cement silo, aggregate silo, clinker silo) Material & Construction: Fabricated from durable Q235 steel, ensuring structural integrity and resistance to corrosion. The bolted design allows modular assembly, facilitating transportation and on-site installation. Capacity & Application: With a 500-ton storage capacity, it supports continuous operations in prefabricated concrete plants or batching plants, minimizing downtime caused by material shortages. Functional Design: Optimized for efficient material discharge and controlled dispensing, maintaining consistent mix quality in concrete production. Its sealed structure prevents moisture ingress and material contamination1. Versatility: Suitable for storing diverse powdered or granular materials, including cement, fly ash, and silica, making it adaptable to various industrial needs. This silo type is integral to modern batching plants, combining high-volume storage with robust engineering for reliable performance in demanding environments. |

|

|

Dimension Sheet:

|

|

|

|

|

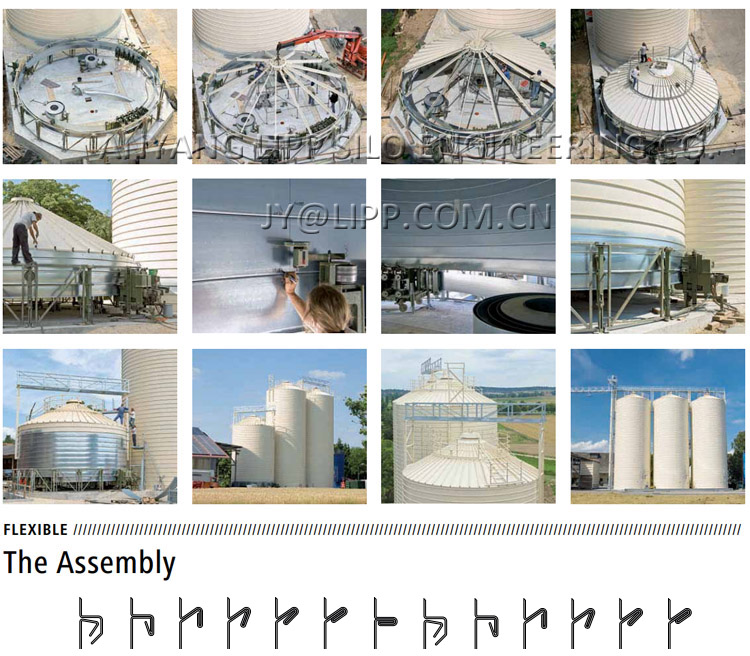

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs Ø Minimal installation space required |

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection Ø Low maintenance costs |

|

|

|

About Us

|

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture established between Anyang Lipp Silo Co.,Ltd and its German partner, Lipp GmbH, specializing in the production of Lipp silo, also known as spiral silo. With registered capital of RMB20 million, fixed assets over RMB150 million, Anyang Lipp is also a certified contractor of steel structure construction and environmental-friendly projects. Among all its competitors, the company is the first to get ISO9000 certificate, capable of doing research, design, fabrication and installation. Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc. With superior product and service, Anyang Lipp has served many domestic and international enterprises including Carlsberg, Heineken, Wilmar, M+W Group, Netafim, Lafarge, Royal Cement, COFCO, etc. With over 500 employees, Anyang Lipp can build steel silo with the total capacity of 5 million m3 per year. About 120 technical staffs and engineers strengthen the company’s competitive edge, making us the most productive and reputed steel silo manufacturer in China. |

|

|

Spiral silo (Lipp silo) offer several advantages in cement storage, making them a preferred choice in industrial applications: 1. Durability and Structural Integrity 2. Moisture and Contamination Protection 3. Efficient Material Handling 4. Customizable and Scalable Design 5. Cost-Effective Maintenance 6. These features collectively enhance storage safety, operational efficiency, and economic viability in cement management systems. |

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|

|

FAQ:

Batching Plant Silo Q1: What is a batching plant silo used for? A1: A batching plant silo is primarily used for the storage of bulk materials such as cement, fly ash, aggregates, and other additives required for the production of concrete or other construction materials. It ensures a continuous supply of materials to the batching plant for efficient mixing and production.Q2: How does a silo work in a batching plant? A2: In a batching plant, the silo acts as a storage container where materials are loaded via conveyors or pneumatic systems. When needed, the materials are discharged through a system of gates, screws, or pneumatic conveyors into the batching plant's mixing unit, where they are proportioned and mixed according to the specific recipe for the desired concrete or other product.Q3: What are the different types of silos used in batching plants? A3: There are several types of silos used in batching plants, including: # Stationary silos: These are permanently installed and typically have a larger capacity. # Mobile silos: These are portable and can be moved to different job sites. # Spiral silos: Known for their quick installation and high structural strength. # Flat-bottom silos: Suitable for storing materials that require a flat surface for discharge. # Cone-bottom silos: Facilitate gravity flow of materials. |

|