Stahlzement Silo für Chargenanlage Stahlbeine

$79999-84999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,QINGDAO,SHANGHAI |

$79999-84999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | ALASHANKOU,QINGDAO,SHANGHAI |

Modell: LPC1500

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

| Herunterladen | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

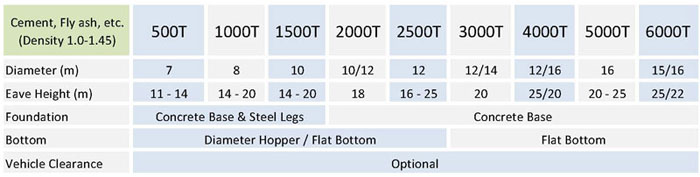

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

Dimension Sheet:

|

|

|

|

|

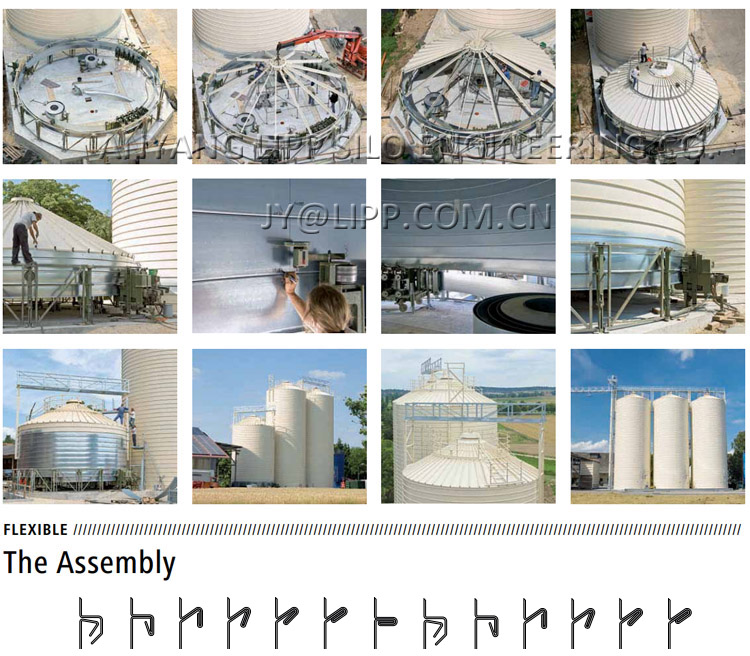

LIPP® DOUBLE-SEAM / SPIRAL RIB

|

|

|

Conventional systems are often unsuitable for the optimum, safe storage of solid or liquid substances and their use can result in premature corrosion, leaks and problems with safety. Flexibility is another important factor. Tanks must be flexible in terms of size and substrate and optimally adaptable to the local conditions. |

|

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs Ø Minimal installation space required |

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection Ø Low maintenance costs |

|

|

|

About Us

|

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture established between Anyang Lipp Silo Co.,Ltd and its German partner, Lipp GmbH, specializing in the production of Lipp silo, also known as spiral silo. With registered capital of RMB20 million, fixed assets over RMB150 million, Anyang Lipp is also a certified contractor of steel structure construction and environmental-friendly projects. Among all its competitors, the company is the first to get ISO9000 certificate, capable of doing research, design, fabrication and installation. Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc. With superior product and service, Anyang Lipp has served many domestic and international enterprises including Carlsberg, Heineken, Wilmar, M+W Group, Netafim, Lafarge, Royal Cement, COFCO, etc. With over 500 employees, Anyang Lipp can build steel silo with the total capacity of 5 million m3 per year. About 120 technical staffs and engineers strengthen the company’s competitive edge, making us the most productive and reputed steel silo manufacturer in China. |

|

Referenzprojekte weltweit:

Kasachstan Alma Ata Cement Company

|

Specification: |

D8 x H15.8 x 8 |

|

Contents: |

Cement clinker, slag, fly ash and cement |

Kamchay Wasserkraft Station Kambodscha

|

Specification: |

D10 x H14 x 8 |

|

Contents: |

Bulk cement, slag powder |

Ägypten Royal Cement Company

|

Specification: |

D15 x H28.5 x 2 |

|

Contents: |

Cement clinker, slag, fly ash and cement |

Indonesien Cement Company

|

Specification: |

D12m x H17.8m x 4 |

|

Contents: |

Cement, slag |

Vietnam -Songbang -Wasserkraftstation

|

Specification: |

D10 x 14 x 4 |

|

Contents: |

Cement |

Russland Beaton Co., Ltd.

|

Specification: |

D8m x H20m x 2 |

|

Contents: |

Cement |

Afrika Lesotho Metolong Stamm Projekt

|

Specification: |

D10m x H14m x 5 |

|

Contents: |

Cement, water tank |

Birma Mandalay Silberperlzement

|

Specification: |

D12 x H25.5 x 6 |

|

Contents: |

Cement |

Brunei Port Cement Silo Project

|

Specification: |

D17 x H27.2 x 2 |

|

Contents: |

Cement |

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|

|

a) FAQ: Batching Plant Silo

Q6: How do I prevent material segregation in the silo? A6: Material segregation can be minimized by: # Using aeration systems: These systems keep the material in motion, preventing segregation. # Proper filling techniques: Fill the silo evenly to avoid creating piles or voids. # Discharge management: Use a first-in, first-out (FIFO) discharge method to ensure even material usage. Q7: What safety measures should be in place for operating a silo? A7: Safety measures for operating a silo include: # Proper training: Ensure all operators are trained in silo safety and operation. # Personal protective equipment (PPE): Workers should wear appropriate PPE, such as helmets, gloves, and respiratory protection. # Confined space entry procedures: Follow safe procedures for entering and working inside the silo. # Ventilation: Ensure adequate ventilation to prevent dust accumulation and asphyxiation risks. # Emergency procedures: Have emergency shutdown procedures and rescue plans in place. |

|