Zementsilo für die Bahnübertragungszugbelastung

$64999-69999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | Q,I,N |

$64999-69999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | Q,I,N |

Modell: LPC1500

Marke: Lipp

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

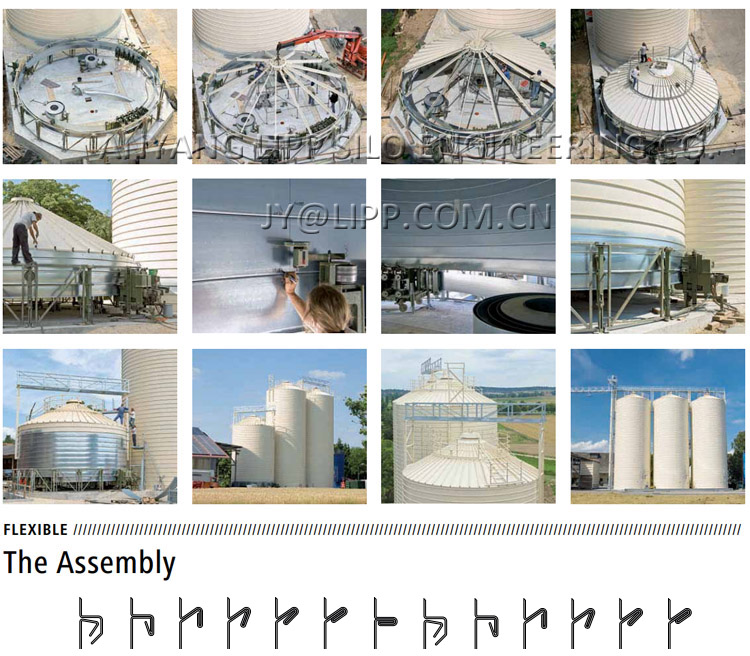

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs Ø Minimal installation space required |

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection Ø Low maintenance costs |

|

|

|

About Us

|

|

|

|

|

As a model of Sino German industrial cooperation, Anyang Lip Silo Engineering Co., Ltd. was established with a joint investment of 20 million yuan from Anyang Lip in China and Lipp GmbH in Germany, focusing on innovating the technology of spiral silos (Lipp Silo). Relying on Germany's century old spiral coil warehouse patent technology and China's heavy-duty steel structure qualification (with registered assets exceeding 150 million yuan), we have built a full value chain from material research and development to EPC general contracting. We are now the only spiral warehouse manufacturer in the Asia Pacific region to hold both ISO9000 international quality system and environmental engineering professional contracting certifications.

With four decades of industry leadership, our organization has successfully delivered over 10,000 specialized steel-plate storage solutions across diverse sectors including agricultural processing (grain & feed), beverage production, construction materials manufacturing, renewable energy (biogas), and industrial materials handling. Our expertise now extends to cutting-edge environmental sectors such as sustainable water management, municipal waste remediation, and energy byproduct containment systems, while maintaining strict compliance with global quality benchmarks.

|

|

|

Containers for water, waste water, sewage sludge

|

|

|

In the fabrication of liquid storage vessels, material choice plays a critical role in corrosion resistance, achieving optimal barrier properties, and maintaining operational integrity. Conventional options like aluminum, zinc-coated steel, or premium-grade stainless steels are frequently considered. Notably, the innovative "Verinox" hybrid material system engineered by Lipp demonstrates superior economic efficiency, delivering exceptional performance-to-cost advantages in containment applications.

|

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|