Sojabohnensilo für die Ölverarbeitungsanlage

$100000-110000 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,SHANGHAI,ALASHANKOU |

$100000-110000 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,SHANGHAI,ALASHANKOU |

Modell: LPG5000

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

|

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

Dimension Sheet:

|

|

|

|

|

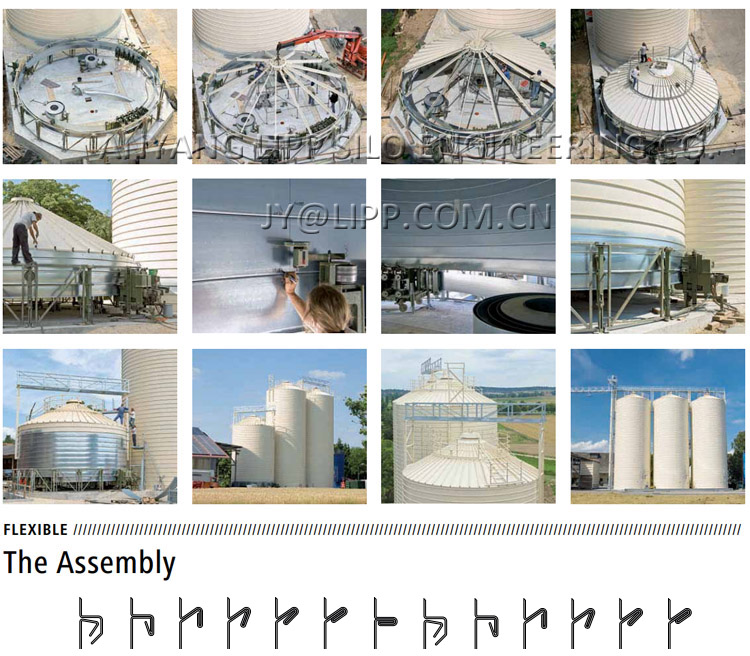

Onsite installation

|

|

|

Using Lipp’s innovative mobile assembly equipment, steel bands can be transformed into customized containers—built directly on-site with variable diameters and dimensions. The streamlined, automated production process ensures quick, efficient, and space-saving installation. Combining speed and simplicity, the Lipp Dual-Seam System provides a superior method for constructing versatile and dependable storage solutions.

|

|

|

Corrosion resistance

|

|

|

They are characterized by outstanding quality. Due to their extreme stability, even the largest containers are resistant to horizontal pressure, meaning maximum safety is ensured. The effective means against premature corrosion: an edgeless, smooth surface on the interior. Another specific benefit: the size of the containers is variable between three and more than 40 meters in diameter.

|

|

|

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

✓ Continuous roll welding seamless process ✓ Super A-level leak prevention guarantee ✓ The most cost-effective installation solution ✓ Ultimate space utilization design |

✓ Mobile factory production

✓ Full spectrum material selection ✓ Medium matching design ✓ Lowest Total Cost of Ownership (TCO) |

|

|

|

About Us

|

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture with its German partner, Lipp GmbH, the founder of Lipp® silo. Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc.

As a leader in the steel silo industry, we have innovatively integrated German precision engineering with Chinese intelligent manufacturing to create a full lifecycle silo solution that integrates classic design, digital production, professional construction, and global operation and maintenance. With the perfect combination of German precision technology and Chinese efficient execution, we have created a truly international warehousing solution.

|

|

|

Milestones

|

|

|

The first year of the Chinese steel plate warehouse in 1985

Shandong Xixia Distillery Project Completed, Pioneering China's Steel Plate Warehouse Received the "China Warehousing Equipment Technology Breakthrough Award" 1993-1996 period of technological leadership ✓ Establish the industry's first professional design and research institute Winning the bid for the Steinecker project in Germany and Lionna Than international project in New Zealand ✓ Received the "China Machinery Industry Science and Technology Progress Award" The period of breakthrough in scale from 1998 to 2001 Taiwan Unification Group's 10000 ton silo Qingdao 38 meter diameter sewage treatment tank Annual production capacity exceeds 500000 tons The period of diversified development from 2006 to 2012 ◇Annual revenue exceeds 100 million yuan ◇ Obtained the certification of "National High tech Enterprise" ◇Complete a 7000m ³ biogas project Global layout period from 2013 to 2021 The 10000th silo has been completed ☆ Business coverage in 14 countries and regions ☆ Achieved 470 million EPC+O project |

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|