Kohlelager Silo -LKW -Ladung Silo

$69999-74999 /Set/Sets

| Zahlungsart: | D/P,T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | TIANJIN,SHANGHAI,QINGDAO |

$69999-74999 /Set/Sets

| Zahlungsart: | D/P,T/T,L/C |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | TIANJIN,SHANGHAI,QINGDAO |

Modell: LPC4000

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

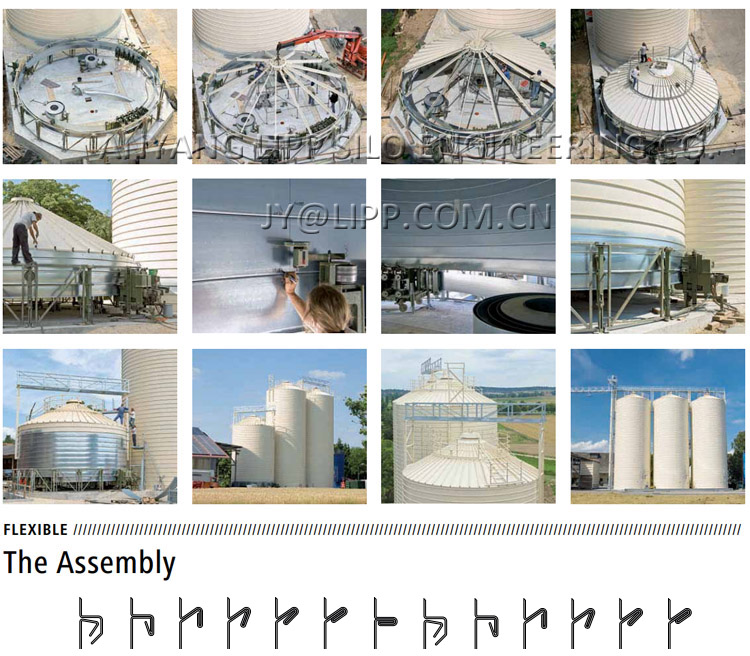

Advantages of Lipu Steel Plate Warehouse:

|

|

|

1.Efficient Material Handling

Integrated systems like screw conveyors (commonly used in cement silos) enable automated and precise material transfer, reducing manual labor and improving operational efficiency in batching plants.

2.Customizable and Scalable Design

Lipp silos can be tailored to specific capacity requirements, from small-scale units to large-scale installations. Modular construction allows for easy expansion or relocation as storage needs evolve.

3.Cost-Effective Maintenance

With corrosion-resistant galvanization and simplified structural components, Lipp silos require minimal upkeep. Long-term warranties (e.g., 1-year coverage) further ensure reduced lifecycle costs.

|

|

|

LIPP® DOUBLE-SEAM / SPIRAL RIB

|

|

|

|

|

About Us

|

|

|

|

|

Core technical parameters demonstrate leadership position:

The technical supervision team of Lip GmbH in Germany is stationed to provide guidance and ensure that the process is iterated synchronously with the Hanover headquarters.

|

|

|

Milestones

|

|

|

1985

|

We built the first Lipp silo for Xixia Distillery in Shandong Province, China, filled the gap of Chinese steel silo construction. |

| 1991 | We built the highest steel silo with the height 33m in Lianyungang, it became a milestone in Chinese storage field. |

| 1993 | we built the first silo design institute of China; |

| 1996 | We became the first Chinese company won the international invitation of tender in steel silo field (German Steinecker GMBH, New Zealand Lionna Than Company ) |

| 1998 | We built the biggest steel silo for Uni-President group of Taiwan. |

| 2001 | We built the biggest steel tank (dia. 38m) for Chengyang waste water treatment factory, Tsingdao. |

| 2006 | Annual turnover exceeded RMB120 million; turnover exceeds 100 million for 3 consecutive years. |

| 2011 | Given the title “National High & New Technology Enterprise” Annual turnover exceeded RMB250 million |

| 2012 | The chicken farm CSTR anaerobic reaction system (total capacity 7000m3) in Beijing was finished, marking a big step forward for China in the biogas exploitation field. |

| 2013 | Anyang Lipp built the 10000th steel silo, erected silos over 14 countries; |

| 2014 |

Became the first to get ISO9000, ISO14001 and ISO45001 certificates among the peers |

| 2018 |

Introduce SM80 equipment from Germany, starting making spiral welding silo |

| 2019 |

Company move to the modernized brand-new facility |

| 2021 | Secured Anyang Eco-Industrial Park EPC+O project with contract price CNY470 million |

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|