Stahltrichter Silo -Entladung Silo -LKW -Lastwagen Beladung

$75999-79999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,TIANJIN,SHANGHAI |

$75999-79999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,TIANJIN,SHANGHAI |

Modell: LPC1500

Marke: Lipp

Stand: Neu

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

| Advantages of Lipu Steel Plate Warehouse | |

|

1.Durability and Structural Integrity

Steel silos are built to withstand harsh environmental conditions and heavy loads, ensuring long-term reliability. The use of Galvanized steel coil (2-4mm) and advanced roll-forming techniques enhances their resistance to wear and deformation.

2.Moisture and Contamination Protection

Their airtight design prevents moisture ingress, which is critical for maintaining cement quality. Steel construction also minimizes risks of pest infiltration or chemical reactions that could degrade stored materials.

3.Efficient Material Handling

Adopting mechanized feeding systems such as rotary screw conveyors (standard configuration for bulk cement storage) to achieve automated and precise control of material transportation. This industrial grade conveying device significantly improves the operational accuracy and processing capacity of concrete mixing plants through programmable logic control, while reducing the need for manual intervention, ensuring material flow stability and process repeatability.

|

|

|

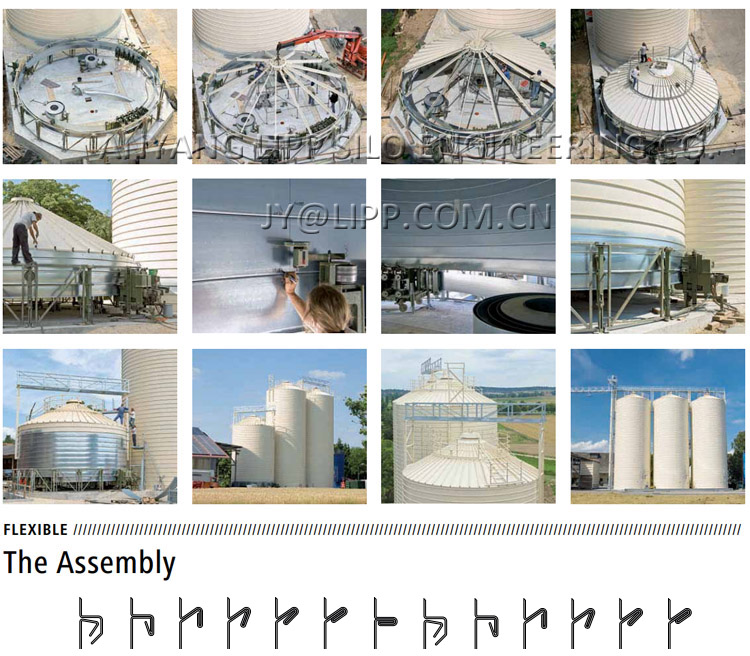

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs

|

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection

|

|

Innovative modular storage tank solution

We use advanced Lip bimetallic welding technology to create an economical and efficient high-capacity storage system (with a single can capacity of over 10000m ³), and its unique mobile on-site canning process can achieve: Rapid construction deployment under complex terrain conditions ✓ Shorten the construction period by more than 50% compared to traditional methods ✓ High precision installation that fully adapts to the terrain of the site Safety protection system Equipped with pressure adaptive dome structure Explosion proof pressure relief system certified by ISO • Complies with the EU ATEX explosion-proof directive requirements • Exclusive pressure balance channel design effectively eliminates the risk of dust explosion |

|

|

|

|

About Us

|

|

|

|

|

Since its establishment in 1984, Anyang Lipu has successfully built over 10000 steel plate silos worldwide, with projects covering more than 20 countries and regions including China, the United States, Russia, Kazakhstan, Malaysia, and Egypt.

We innovate through the integration of Chinese and German technologies: Deeply integrate intelligent technology with the concept of sustainable development ✓ Creating an automated warehousing solution that seamlessly integrates digital and physical systems ✓ Redefine modern warehousing standards with revolutionary engineering efficiency |

|

|

Milestones

|

|

|

1985

|

We built the first Lipp silo for Xixia Distillery in Shandong Province, China, filled the gap of Chinese steel silo construction. |

| 1991 | We built the highest steel silo with the height 33m in Lianyungang, it became a milestone in Chinese storage field. |

| 1993 | we built the first silo design institute of China; |

| 1996 | We became the first Chinese company won the international invitation of tender in steel silo field (German Steinecker GMBH, New Zealand Lionna Than Company ) |

| 2001 | We built the biggest steel tank (dia. 38m) for Chengyang waste water treatment factory, Tsingdao. |

| 2006 | Annual turnover exceeded RMB120 million; turnover exceeds 100 million for 3 consecutive years. |

| 2011 | Given the title “National High & New Technology Enterprise” Annual turnover exceeded RMB250 million |

| 2012 | The chicken farm CSTR anaerobic reaction system (total capacity 7000m3) in Beijing was finished, marking a big step forward for China in the biogas exploitation field. |

| 2013 | Anyang Lipp built the 10000th steel silo, erected silos over 14 countries; |

| 2014 |

Became the first to get ISO9000, ISO14001 and ISO45001 certificates among the peers |

| 2018 |

Introduce SM80 equipment from Germany, starting making spiral welding silo |

| 2019 |

Company move to the modernized brand-new facility |

| 2021 | Secured Anyang Eco-Industrial Park EPC+O project with contract price CNY470 million |

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|