Stahlsilo Hopperboden für Chargenanlage

$39999-59999 /Set/Sets

| Zahlungsart: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,TIANJIN,SHANGHAI |

$39999-59999 /Set/Sets

| Zahlungsart: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

| Hafen: | QINGDAO,TIANJIN,SHANGHAI |

Modell: LPC1500

Marke: Lipp

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

| Herunterladen | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

| Applicable Fields: | |

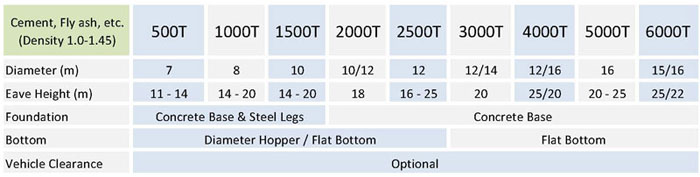

| Cement, fly ash, slag, mine powder, plaster, coal, chemicals, etc. | |

|

Specification:

|

|

|

Diameter: 3.5 - 38 m |

|

|

Dimension Sheet:

|

|

|

|

|

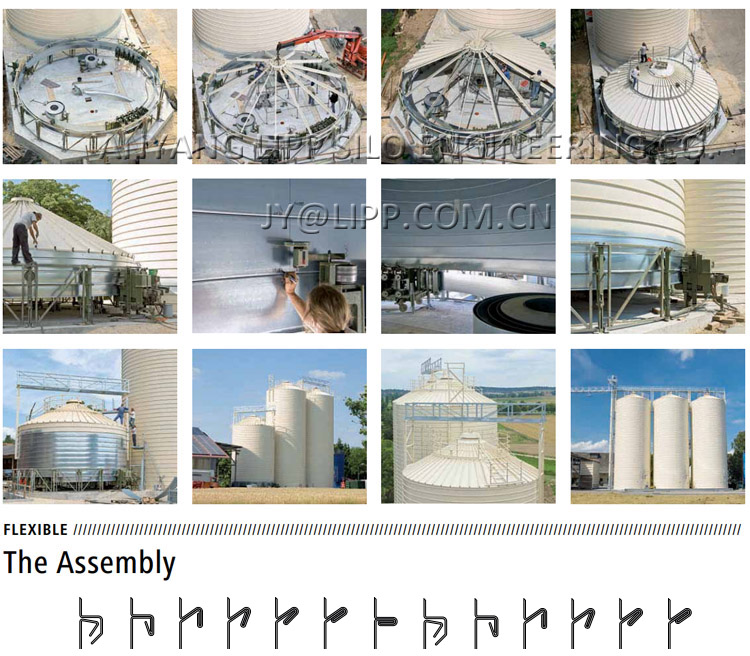

LIPP® DOUBLE-SEAM / SPIRAL RIB

|

|

|

The traditional storage tank system has significant limitations in the safe storage of solid and liquid substances - insufficient material compatibility can easily lead to early corrosion failure, and the rigid design of the structure is difficult to adapt to site variables, resulting in decreased sealing and operational risks. Modern engineering solutions need to break through standardization limitations and achieve precise coupling between tank systems and terrain features, environmental loads, and process requirements through modular size adjustment and multi material matching capabilities. |

|

THE BENEFITS OF THE LIPP SPIRAL SILO/TANK

|

|

|

Ø Edgeless, smooth finish Ø Maximum leak-tightness Ø Automated, efficient production on site Ø Low installation and investment costs Ø Minimal installation space required |

Ø High static and dynamic stability Ø Available in stainless steel, VERINOX® stainless steel or galvanized/black steel Ø Substrate-flexible due to specific material selection Ø Low maintenance costs |

|

|

|

About Us

|

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture with its German partner, Lipp GmbH, the founder of Lipp® silo. Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc.

Over 40 years of operational excellence have positioned us as the preferred partner for industrial storage needs, having engineered more than 10,000 durable metal-clad facilities serving food processing, construction materials, chemical production, and port logistics sectors. Our progressive expansion into green technology markets - including circular economy solutions for water purification, organic waste-to-energy conversion, and industrial byproduct management - demonstrates our commitment to global sustainability standards.

|

|

|

Milestones

|

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|

|

a) FAQ: Batching Plant Silo Q8: How do I troubleshoot common issues with silos? A8: Common issues and troubleshooting steps include: # Material bridging: Use vibrators or aeration to break up bridges. # Clogging or jamming: Check and clear any obstructions in the discharge system. # Leakage: Inspect and repair any leaks in the silo or its connections. # Overfilling: Install level indicators to prevent overfilling and material spillage.

# Corrosion: Regularly inspect and repaint or repair corroded areas. |

|