CSTR anaerobe Reaktionstank für die Geflügelzucht

$69999-79999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

$69999-79999 /Set/Sets

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 1 Set/Sets |

| Transport: | Ocean,Land |

Modell: LPT2500

Marke: Lipp

Kunst: Lagertank

Garantiezeit: 1 Jahr

| Verkaufseinheiten | : | Set/Sets |

The file is encrypted. Please fill in the following information to continue accessing it

|

- Waste water tank

- Sewage sludge tank

- Process water tank

- Storage tank

- Firefighting water tank

|

- Mixing and compensation tank

- Buffer tank

- Stackable sludge tank

- Filtrate water tank

- Final sedimentation tank

Other special tanks on request

|

|

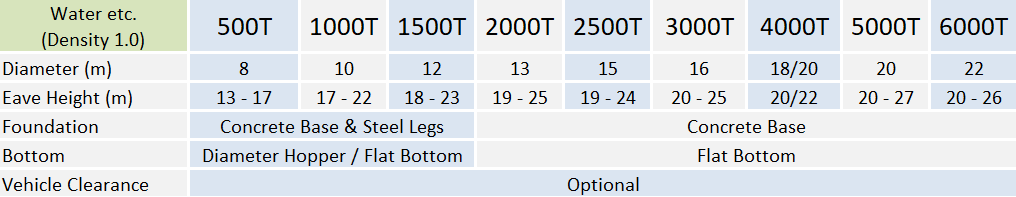

Technical Data

Diameter: 3.5 - 38 m

Height: 5 - 23 m

Volume: 100m3 - 10,000m3

pH level: 3 - 13

|

Accessories

Roofs and covers

Tank bottom

Pumping and mixing technology

Tank insulation

Stairways, ladders, platforms, connection pieces, manholes, etc.

|

|

|

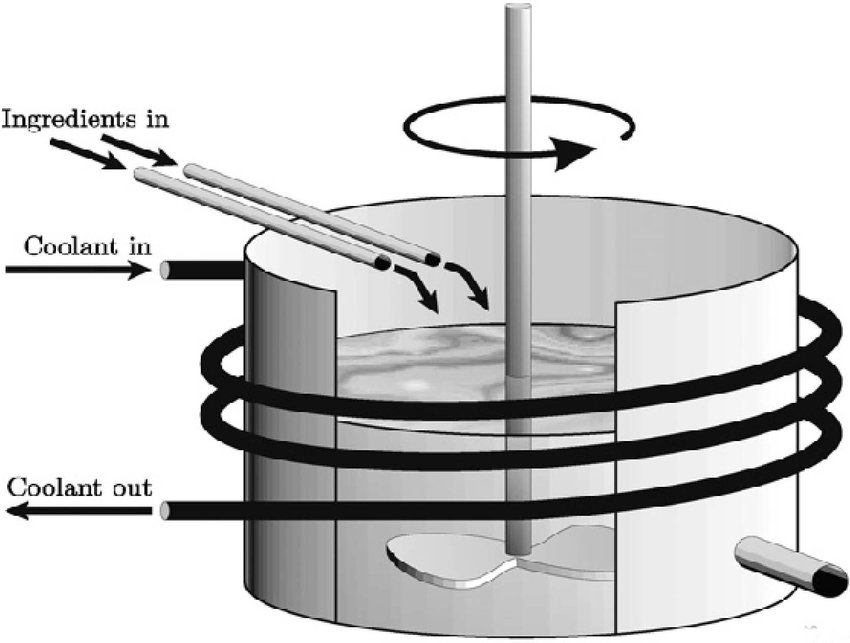

A Continuous Stirred Tank Reactor (CSTR) is a vital industrial and laboratory apparatus designed for continuous chemical processes. It enables steady-state operation by continuously feeding reactants into a well-mixed tank and withdrawing products at the same rate. Its design ensures uniform temperature, concentration, and reaction kinetics throughout the vessel via mechanical agitation.

|

|

|

|

Anyang Lipp Silo Engineering Co.,Ltd is a joint venture with its German partner, Lipp GmbH, the founder of Lipp® silo. Founded in 1984, Anyang Lipp has built over 10,000 steel silos in China and other countries like USA, Russia, Kazakhstan, Mongolia, Malaysia, Egypt, Zambia, Indonesia, Cambodia, Brunei etc.

|

|

|

Company Tour

|

|

|

|

| Delivery Preparation | |

|

|

Key Features

|

|